Stud welding machine Safety majors for Stud welding machine transportations

Akshay Fasteners has a set of Stud welding machine safety majors and Stud welding machine transportation. These Stud welding machine safety majors for Stud welding machine transportation are subject to strict internal and external regulations. These regulations illustrate the proper use of stud welding machines conditions for Stud welding machine after sale service

The regulation describes how the stud welding machine safety majors, how they are being packed, as well as other Stud welding machine exporter requirements, met to reduce the chance that packages would not be damaged or hampered during the Stud welding machine transportation or Stud welding machine exporter. It also helps in reducing the likelihood of accidents.

Akshay Fasteners is ISO 9001 certified company leading stud welding machine Manufacturer and a reliable stud welding machine exporter who assures the best stud welding machine safety majors for the stud welding machine transportation and the stud welding machine after sale services.

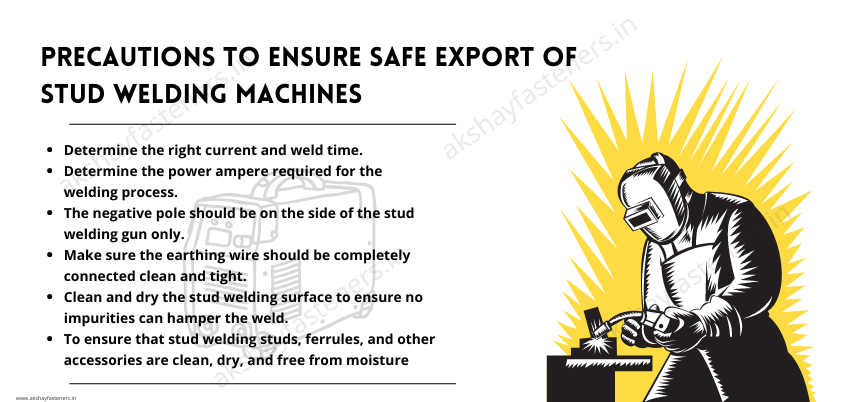

Precautions to ensure safe export & transportation of Stud Welding Machines

Stud welding machines create strong, clean, and long-lasting welding solutions using stud welding studs and stud welding guns. For the smooth functioning of stud welding machines, certain precautions must be adopted.

Stud welding guns are lightweight, easy to carry, and require less power.

Guidance on How to use Stud Welding Machine

1: Basic preparation Stud welding Machine set up:

The stud welding machine is used to join the studs and base metals. But before that base meta should be prepared which involves cleaning and rusting the metals from unwanted grease, dust, and other impurities. It provides the right formation for a good stud welding

2: Use stud welding machine wearing welding gears:

Stud welding is a complex welding process proper precaution should be maintained to reduce the chance of accidents. To reduce the chances of unwanted incidents Welding gear are provided which includes safety shoes, safety glasses, safety gloves, safety robes, etc. Akshay Fasteners is a certified stud welding machine manufacturer and a global stud welding machine exporter

3: Securing the stud welding machine work area:

Stud welding machines are heavy machinery that requires a secure workplace. The platform on which stud welding machines are set up should be secured and safe from unwanted environments like fireproof, waterproof and it should be placed nearby to the main power source. Stud welding machine manufacturers are required to assure that proper stud welding machine safety majors are followed in the stud welding machine transportation.

4: Securing stud welding machine accessories:

Stud welding machines require essential accessories for the efficient and effective operations of the stud welding process. The accessories should be tested and verified on the standard testing parameters. Lack of proper accessories increases the chance of accidents and errors.

5: Welding the joints

Stud welding machine strikes the arc by establishing a base metal workpiece with the studs for a few milliseconds and pulling it back. When the studs are in contact with the base metal workpieces, the studs circuit gets completed, which produces the heat for melting the studs and it begins the formation of the welding joints.

6: Appropriate position and functions:

It is an important factor that stud welding machines should be placed at the right positions for the proper functioning of the stud welding process. It is good practice to set up the stud welding machine near the arc welding machine and shear stud welding machine. The length of CD welding Studs And Arc welding studs also affects the positioning of stud welding machines.

7: Cleaning and painting stud welding machines

Cleaning and painting the stud welding machines enhance the effective life of the stud welding machine. It also increases the productivity of the stud welding machine and reduces the breakdown and machine. Which ultimately results in an overall increase in return on investment. Akshay Fasteners is the leading stud welding machine manufacturer nationwide having offices across India for Stud welding machine after sales services.

Stud Welding Machine after sale services in Akshay Fasteners

Stud welding machine performs a complex stud welding process and is used to join the welding studs with the base metals by using the appropriate heat and pressure. Stud welding machines required regular maintenance for effective and productive performance.

Stud welding machines are vulnerable welding machines and require proper care for the operation in addition to that repair and maintenance of stud welding machines are costly that’s why Stud welding machines after sale services policies have become an integral part of stud welding machine manufacturers and stud welding machine exporters.

Akshay fasteners a renowned stud welding machine manufacturer and reputed stud welding machine exporter offers the best stud welding machine safety majors for stud welding machine transportation and stud welding machine after sales services at the most affordable price. Stud welding machine after sale services are provided for a certain period which includes warranty or guarantee to the parts of stud welding machines, free shipment of stud welding machines, repair and maintenance, etc.

Conclusion:

Akshay Fasteners is an eminent name in the stud welding machine manufacturer well-known for Stud welding machine safety majors for the Stud welding machine transportation and Stud welding machine exporter. We provide 24*7 customer services for our customers which includes stud welding machine after sale services.

Akshay Fasteners is also the most reliable and respectable stud welding machine exporter providing the welding equipment at the most affordable stud welding price. Our stud welding machine after sale services not just only meet their requirements but exceed them.