Types of Stud Welding

Stud welding is an advanced form of welding providing instant welding solutions for diverse industries’ needs. Sometimes it only takes milliseconds to weld the metals. Instant and effectiveDrawn Arc welding studs solutions have made stud welding an integral part of the industry.

Type of stud welding you should use may differ from factors like the type of materials used, the thickness of materials, expected time of welding, the intended use of the finish products, etc.

Akshay Fasteners Pune-based company established in 2005 is an ISO certified Company and a renowned CD Welding Studs manufacturer well-known for every type of stud welding product in the industry of stud welding.

Types of Stud Welding in the industry | Akshay Fasteners

CD (Capacitor Discharge) Stud Welding

CD Stud Welding is extensively used for welding solutions where welding aesthetics are in top priority. CD stud welding is well-known for its clean, flawless no blackening stud welding Solutions.

In the CD stud welding, short weld cycles studs are used for providing instant stud welding under low temperature. CD stud welding can also be used for welding on ferrous or non-ferrous welding materials.

Akshay Fasteners is a well-known stud welding machine manufacturer in Pune, India providing the industrial standard high-quality stud welding machines since 2005. Stud welding for sale in Akshay fasteners has the most affordable stud welding machine prices.

How CD Stud Welding works:

The process of CD Stud Welding involves

Akshay Fasteners Pune-based company established in 2005 is an ISO certified Company

Applications of CD Stud Welding

CD Stud Welding provides versatile welding solutions commonly used in the production of the following products

DA (Drawn Arc) Stud Welding

Drawn Arc Stud Welding is famous for its high-quality welding solutions. DA stud welding is specialized for higher diagram studs where the welding strength is at the utmost priority. DA stud welding is used for heavy industrial welding solutions.

DA stud welding requires certain technical expertise for the effective operation of stud welding machines. DA stud welding requires minimum additional material which makes it one of the most cost-effective types of stud welding.

DA stud welding provides heavy industrial leak-resistant welding solutions which have high structural strength and integrity. DA stud welding has high melting points which provide long-lasting effective welding solutions.

The process of Drawn ARC welding involves:

Applications of DA (Drawn Arc) Stud Welding

DA Stud Welding provides heavy industrial welding solutions extensively used in producing the following products:

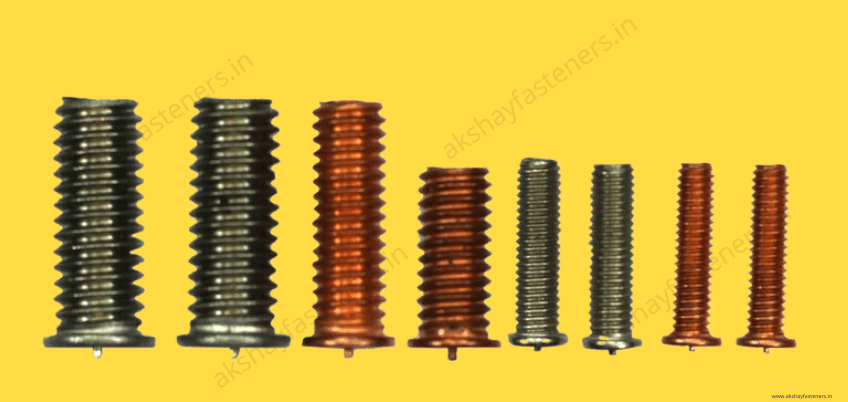

Why Choose CD Welding Studs(Threaded)

CD Welding Studs(Threaded) are well accepted in the welding industry for their instant, clean, and durable welding finishes. In the CD welding Studs (Threaded) process welding is required to be done on the one side only, thus it results in no deterioration on the other side.

As CD welding studs joints are incredibly strong and durable their joints are leakage-resistant even in a detrimental environment as the metals are strongly joined with heat. In addition to that, it does not leave any mark or blackening on the other side of the materials.

Akshay Fasteners is an expert CD welding studs manufacturer in the welding industry. We provide CD Welding Studs for every major industry. Our CD Welding Studs(Threaded) are made with high-quality material and tasted on strict ISO verifications standards.

Features of CD Welding Studs(Threaded)

Reasons to opt for Arc welding studs

ARC welding studs are an advanced form of the stud welding process. They are used for welding heavy industrial rougher and thicker materials. Arc welding studs are used for the drawn arc welding process in which fasteners are fusion with parent materials with extreme heat that results in instant welding among the materials.

Arc welding studs are well known for their heavy usage and unparalleled strength in terms of the stud welding process. Arc Welding studs are preferred in the areas where the strength and boundless have great significance on the process.

Akshay Fasteners being a proactive Arc welding studs manufacturer consistently works on innovations and developing new technology to increase the strength and reliability of the CD stud welding and Arc stud welding products.

Advantages of Arc welding studs

Conclusion:

Akshay Fasteners Pune-based ISO certified company is a renowned CD Welding Studs manufacturer providing superior quality CD Welding Studs(Threaded), Arc welding studs, and other weldable fasteners since 2005.

Akshay Fasteners provides weldable fasteners for every type of welding process and have a successful track record of satisfying client’s expectations in the best possible way